PRODUCT INTRODUCTION

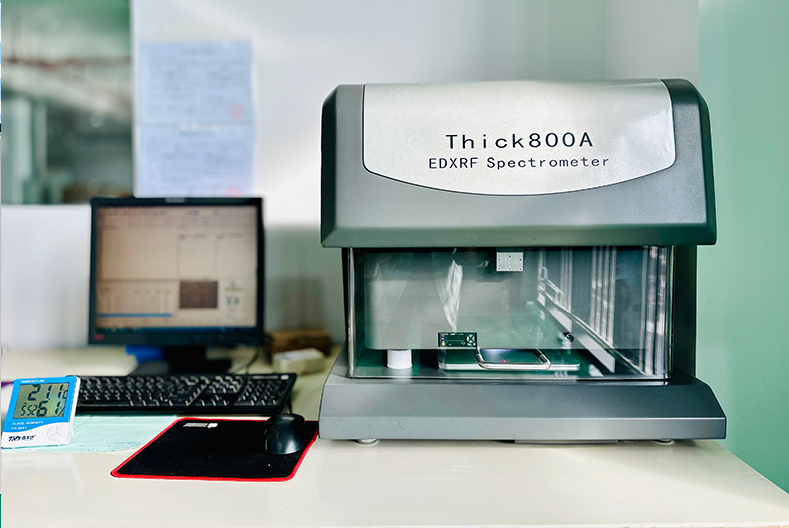

Quality control

-

1、 Strong guarantee for quality improvement

1、 Strong guarantee for quality improvement

The IATF16949 system comprehensively standardizes the production process of automotive electronic products, strongly monitors quality, reduces errors and deviations, safeguards product reliability and stability, reduces quality risks, and helps you win reputation with high-quality products.

2、 Efficient engine for supply chain collaboration

The IATF16949 system comprehensively standardizes the production process of automotive electronic products, strongly monitors quality, reduces errors and deviations, safeguards product reliability and stability, reduces quality risks, and helps you win reputation with high-quality products.

3、 A sturdy shield for risk avoidance

The IATF16949 system enables enterprises to have risk insight and response capabilities, identify risks with professional tools, formulate strategies for prevention and resolution, build a shield for your business, and ensure the safety and predictability of investment cooperation.

4、 The golden signboard of market reputation

This certification is the reputation signboard of automotive electronics enterprises, indicating high standard management norms, winning your trust and recognition. Cooperating with certified enterprises is like standing shoulder to shoulder with elites, helping you expand your business, attract resources, and promote takeoff with the effect of the signboard. -

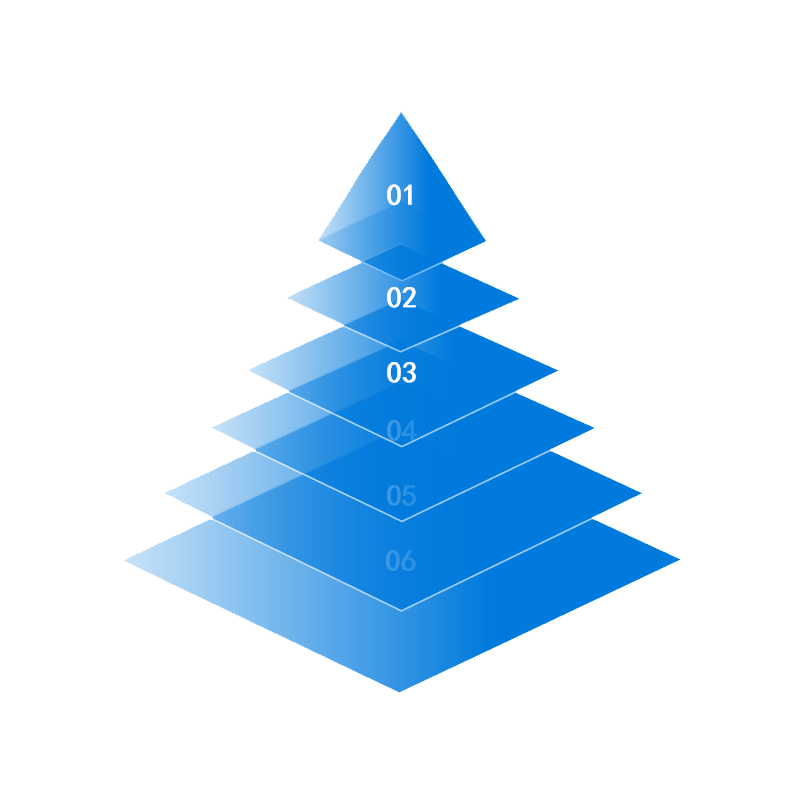

01 Continuous improvement of quality management system

Continuous improvement is the core principle of IATF16949, emphasizing the continuous optimization of the quality management system through the PDCA (Plan Do Check Act) cycle.03 Supplier Management

IATF16949 emphasizes that supplier management is an important component of the quality assurance system, requiring organizations to ensure that suppliers meet quality requirements and regularly evaluate and monitor their quality.05 Process Control

IATF16949 requires strict control of the production process to ensure product quality meets standards. Process control includes monitoring key parameters, using control charts and process capability analysis, and real-time monitoring and adjustment of key control points.02 Preventive Actions

Preventive measures aim to identify potential sources of quality issues and take effective measures to prevent problems from occurring. Common methods include FMEA (Failure Mode and Effects Analysis), risk assessment, and other tools to achieve proactive quality management.04 Product Traceability and Traceability

Traceability ensures that the entire process from raw materials to the final product is traceable. It is crucial for recall management, quality tracking, and compliance, especially in the automotive industry, helping to quickly identify the scope of issues.06 Non conformance Management and Corrective Actions

Nonconforming product management is an important part of the quality assurance system. Organizations must take corrective measures, conduct root cause analysis, implement corrective measures, evaluate their effectiveness, ensure that problems do not occur again, and continuously improve.

Online Service

Online Service